The meat processing industry requires well-engineered equipment to achieve consistent results. The equipment line from Titan Injections is specifically designed and manufactured to meet the challenging requirements of commercial meat processors. Each of our machines aid in the production of outstanding, marinated and tenderized meat.

Titan Injection is globally known for curing and marinating machines that are consistent, accurate, and reliable. We never compromise on quality because we aim to deliver a better end product for your facility. Our equipment has become the industry standard for performance and innovation.

Most importantly, each of our machines is backed by our commitment to exceptional customer service. If your facility requires assistance during the lifetime of your machine, a member of our technical team will be there to find a solution. We are your trusted partner for all of your processing and flavoring needs.

Titan Injectors are proudly made in the USA.

All American parts and standard components assure optimum performance and reliability.

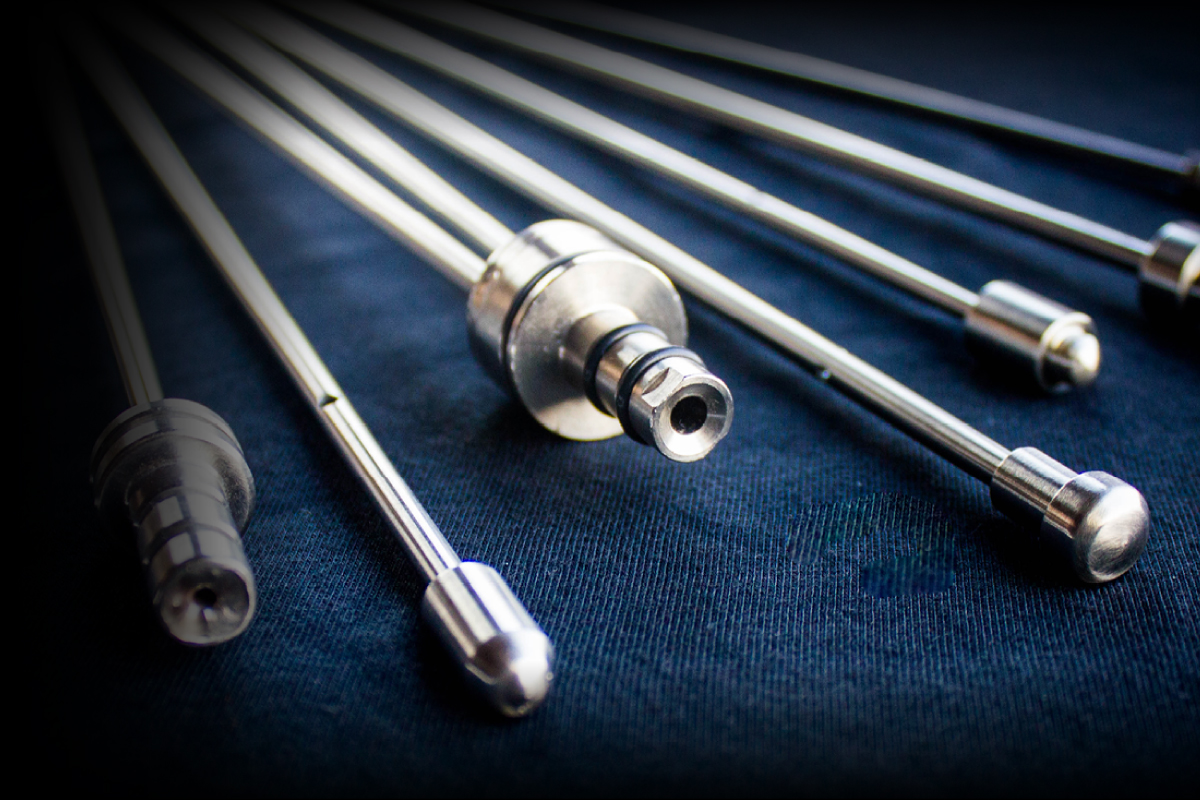

Meat Injectors

Well-engineered machines design to inject brine and other ingredients into fresh meat

Our meat injectors are suitable for all types of additives including regular brines and marinades with high viscosity. Our equipment enables meat processing facilities to maximize production while improving the quality of the finished products.

Needle Flushing Cabinet

Backflush sectional needle blocks from any of our meat injectors to ensure a sanitary environment

Our innovative needle head technology quickly detaches from your Titan series injector for an efficient sanitation process. This cabinet is designed to flush needles in bulk. Individual cleaning is no longer required.

Continuous Tumbler

Remove excess brine from the surface and increase the visual appeal of your product

Increase the visual appeal of your products with the Titan Tumbler. This continuous stainless-steel tumbler removes excess brine from the surface of the meat and seals the needle marks within the product.

Heat Exchangers

A heavy-duty heat exchanger designed to maintain the return bring temperature at 34°

Our heat exchangers are specially designed to support our entire range of meat injectors. They are also designed to work in demanding meat processing facilities where sanitation temperatures are crucial.

Mixing & Cooling

Evenly mix additives and cool brine to the perfect temperature for the injection process

The Titan Twin 200 is a high-performance mixer designed to combine wet and dry additives while keeping the brine cool. High capacity mixing allows for the processing of high viscosity brines and marinades.